- Overview

- Related Products

Product Description

High hardness yellowing resistant epoxy resin river table 3:1 epoxy ab glue Epoxy resin 128E is a bisphenol-A liquid epoxy resin modified with reactive diluent.This resin offers lower viscosity & lower surface tension. Both these properties are advantageous while formulating.

The low viscosity improves the cost effectiveness by increasing filler loading & the low surface tension improves adhesion by better substrate wetting, it also helps in better pigment wetting and thereby improve the pigment dispersion and stability.

Highly transparent and highly resistant to yellow 2:1 or 3:1 river glue

Features:environmentally friendly hard epoxy resin crystal AB adhesive can be room temperature or temperature curing, moderate viscosity, high transparency, self-foaming, self-leveling good, moderate operating time, suitable for manual and mechanical glue drops, curing high hardness, surface flat, high clear and high translucent, gloss, anti-yellowing (can be large volume of a potting 20kg)

|

Product Name

|

highly resistant to yellow 2:1 High transparent 3:1 river table ab glue

|

|

Model

|

128E Epoxy Resin,

|

|

cure agent epoxy

|

3357S, 3357R

|

|

Application

|

Large volume potting glue, wood bonding

|

|

Feature

|

Low viscosity

|

|

Package

|

200kg/drum

|

|

Epoxy Type

|

Bisphenol A

|

|

Appearance

|

Transparent

|

|

Mix Ratio for Epoxy resin EEW=190

|

3:1 or 2:1, depend on models of cure agent epoxy

|

|

Pot life(100g/25℃,minutes)

|

2-5hrs

|

Use process:Ratio: A:B=2:1 and 3:1 optional. Curing: 24 hours at room temperature, 48 hours demolding is recommended at room temperature, 72 hours can be sanded and polished!

Precautions:1. The product to be potting needs to be kept dry and clean. 2. When using, please check the A agent first, observe whether there is any settlement, and mix the A agent well. 3. Take the amount according to the proportion, and weigh accurately, A, B agent mixing fully stirred to avoid incomplete curing. 4. Stir the hook in time for filling, and try to use up the mixed glue within the available time. 5. After filling, the glue will gradually penetrate into the crevices of the product. If necessary, please carry out the second ring, drip glue 6. During the curing process, please keep the environment clean so that impurities or dust will not fall into the surface of the uncured glue.

About part A component-128E liquid clear epoxy resin

128E is modified by Reactive diluent Alkyl(C12-C14) Glycidyl Ether from 128 epoxy, we can provide customized modified epoxy resin 128 type by different ratio of diluents. pls see types of epoxy in below table:

|

Product Code

|

Type

|

EEW (g/eq)

|

Viscosity (25℃,mPa.s)

|

Apperance

|

|

128

|

Bisphenol A

|

184-196

|

11000-15000

|

Transparent Liquid

|

|

128E

|

Bisphenol A

|

190-210

|

1500-3000

|

Transparent Liquid

|

|

128G

|

Bisphenol A

|

190-210

|

700-1500

|

Transparent Liquid

|

|

128EL

|

Bisphenol A

|

200-220

|

500-1000

|

Transparent Liquid

|

|

128BF

|

Bisphenol A modified with Bisphenol F

|

190-210

|

700-1500

|

Transparent Liquid

|

|

128M

|

Bisphenol A

|

180-200

|

5000-10000

|

Transparent Liquid

|

About part B component-epoxy hardener or cure agent

|

Hardener Model

|

Amine value (mgKOH/g)

|

Viscosity 25℃ (mPa.S )

|

Ratio(for Epoxy resin EEW=190)

|

Applications

|

|

Hanamine 3356

|

510-550

|

90-230

|

A:B=4:1

|

repair of micro defects on stone surface

|

|

Hanamine 3357S

|

370-400

|

20-100

|

A:B=3:1

|

river table adhesive

|

|

Hanamine 3357R

|

280-300

|

20-100

|

A:B=2:1

|

river table adhesive

|

Finished Product

Packing & Delivery

200kg/iron drum

Packing & Delivery

220kg or 240kg in iron drum,11000kg in IBC tank

Company Profile

Han Epoxy (Short for Wuhan Jiangling Technology Co.,Ltd) established in 2008,is an enterprise whose main business is the research and development, production, sales, and application services of epoxy new materials; using advanced technology, perfect service, to serve the world's epoxy material customers .

Our main products:epoxy resin, epoxy hardener, epoxy accelerator DMP-30, epoxy reactive diluent AGE, benzyl alcohol, modified aromatic amines, aliphatic amines, alicyclic amines, phenalkamines, polyamides, cardanol epoxy resin curing agents, water-based epoxy curing agents, etc., which are widely used in floor paints, anti-corrosion coatings, and construction .We also have strong market competitiveness in many fields such as structural glue, stone repair, beautiful seam glue, and composite materials. Our production base is located in Dongmafang Industrial Park, Yingcheng City, Hubei Province,China. It covers an area of 30,000 square meters and has a production capacity of 50,000 tons per year ,with 14 national patents and is a national high-tech enterprise. We are establishing a new factory with 68,000 square meters to expand our capacity to meet our customer's demand, and the new factory will be finished by next year. We are willing to sincerely cooperate with friends at home and abroad with first-class products, first-class reputation and first-class service for common development and create brilliant.

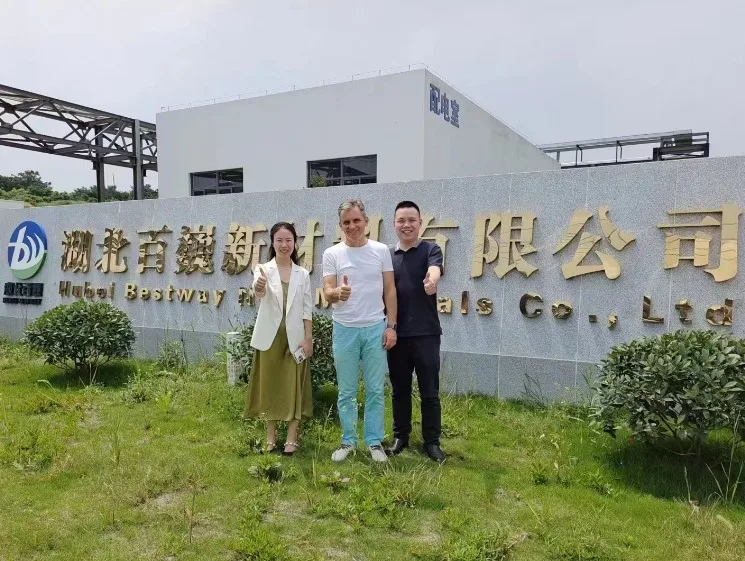

Customer visiting

Exibitions

Partnerships

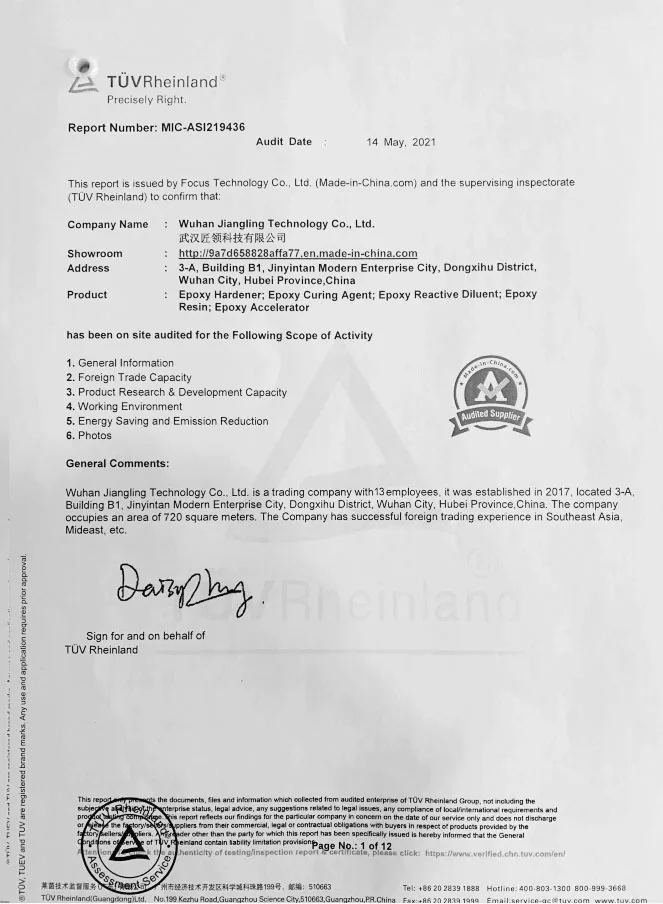

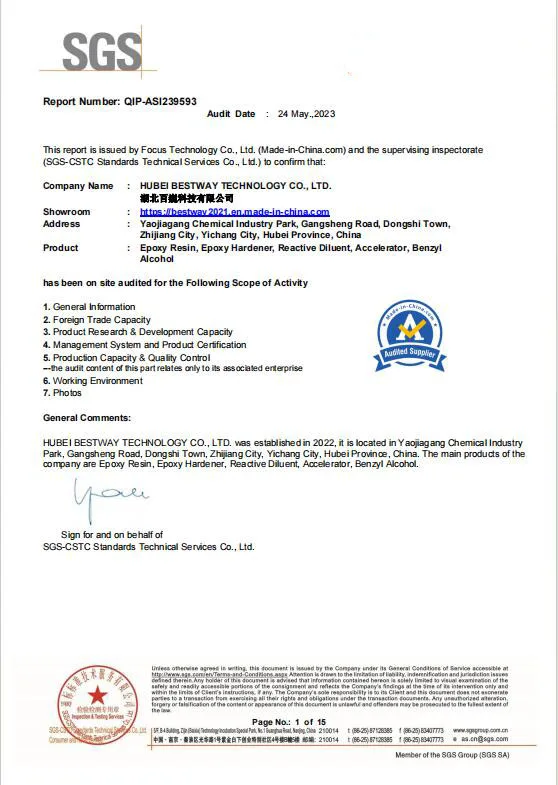

Certification

FAQ

Epoxy floor coating is a kind of high-performance floor coating material, which is widely used in industrial plants, warehouses, garages and other places. The construction process of epoxy floor coating includes three parts: primer, middle and top coat, of which primer curing agent is one of the key components.

The main role of the primer coating is to close the pores of the concrete, enhance the adhesion between the ground base and prevent water vapor, air and corrosive substances from affecting the quality of the epoxy flooring.

The middle coating in the epoxy floor construction plays a role in the beginning and end, not only to help level the base surface, but also increase the thickness of the coating film, improve the bearing capacity and service life.

The top coating provides epoxy flooring with good decorative effect and protective performance, such as anti-static,

wear-resistant, anti-skid, corrosion-resistant and so on.

The main role of the primer coating is to close the pores of the concrete, enhance the adhesion between the ground base and prevent water vapor, air and corrosive substances from affecting the quality of the epoxy flooring.

The middle coating in the epoxy floor construction plays a role in the beginning and end, not only to help level the base surface, but also increase the thickness of the coating film, improve the bearing capacity and service life.

The top coating provides epoxy flooring with good decorative effect and protective performance, such as anti-static,

wear-resistant, anti-skid, corrosion-resistant and so on.

2.What curing agents do we offer and how do they behave in epoxy resins?

√.Polyamides:produced by reacting dimerized and trimerized vegetable oleic acid or unsaturated fatty acids with polyamines. They have very good elasticity, adhesion and water resistance, good constructability, low toxicity, but lower heat resistance, usually the heat distortion temperature is only about 50 ℃. It is suitable for construction in humid environment, but the curing speed is slow, may need to add accelerator,suitable for anticorrosive primer, floor paint and so on.

√Aliphatic amines:this kind of curing agent has large dosage, mostly liquid, good miscibility with epoxy resin, can be cured at room temperature, but heat resistance is not high, usually need to be heated after curing to improve heat resistance.√Aromatic amine:the molecular structure contains benzene ring, alkaline, and epoxy resin reactivity is small, usually need to be heated curing, curing material has good heat resistance, drug resistance and mechanical properties,its modified curing agent can be applied to the floor primer.

√Alicyclic amines:containing alicyclic structure of amine compounds, generally low-viscosity liquid, with a longer period of application and good mechanical strength, modified products can be cured at room temperature,suitable for epoxy flooring finishes and so on.

√Polyether amines:These curing agents can enhance the elasticity, toughness, impact resistance and flexibility of the cured material, low viscosity, low color, low price,modified products can be applied to the floor paint materials in the paint and top coat, also suitable for the production of epoxy jewelry glue.

√Anhydride curing agent:By reacting with the hydroxyl group in the epoxy resin, it forms a stable cross-linking structure, which improves the thermo-mechanical properties and insulating properties of the material. Compared with amine curing agents, they usually need to be baked at higher temperatures to cure completely, and are usually used in the field ofglass fiber reinforced polymer materials.